Introduction to the three-point injection molding process in

欄目:Industry News 發(fā)布時間:2021-06-03 15:19

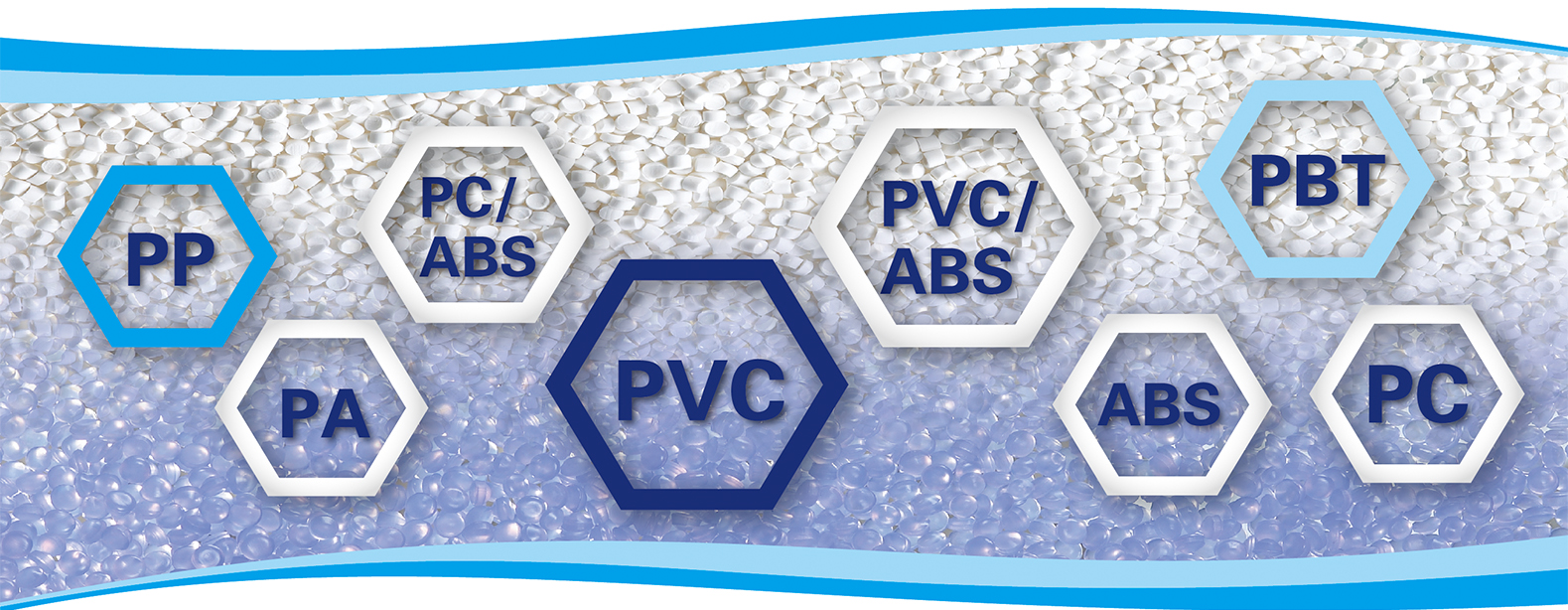

Injection molding is a method of industrial product production modeling. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding molding method and die castin...

Injection molding is a method of industrial product production modeling. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding molding method and die casting method.

Injection molding machine (referred to as injection molding machine or injection molding machine for short) is the main molding equipment for making thermoplastic or thermosetting materials into plastic products of various shapes using plastic molding molds. Injection molding is achieved by injection molding machines and molds.

So, here are some injection molding processes that affect the strength of injection molded parts:

1) Increasing the injection pressure can improve the tensile strength of modified PP injection molded parts

Modified PP material is more elastic than other hard rubber materials, so the density of injection molded parts will increase with the increase of pressure. This feature is relatively obvious. When the density of plastic parts increases, its tensile strength will naturally increase, otherwise it will decrease.

However, when the density increases to the maximum value that PP itself can reach, if the pressure is increased, the tensile strength will not continue to increase. Instead, it will increase the residual internal stress of the injection molded part and make the injection molded part brittle.

Other materials have a similar situation, but the degree of obviousness will be different.

2) The injection of hot oil in the mold can improve the strength of the steel parts and modified nylon parts

Modified nylon and POM materials are both crystalline plastics. The mold is transported by hot oil machine for hot oil injection, which can slow down the cooling rate of the injection molded parts and improve the crystallinity of the plastic. At the same time, due to the slowing of the cooling rate, the residual internal stress of the injection molded parts is also reduced. Therefore, the impact resistance and tensile strength of modified nylon and POM parts injected with hot oil for hot oil injection will be improved accordingly.

It should be noted that the size of nylon and POM parts that are injected with hot oil in hot oil injection will be slightly different from that of water injection, and nylon parts may be larger.

3) The speed of melting glue is too fast.

Under normal circumstances, PVC pellets -90 degree material is injection molded at 180 ℃, the temperature is enough, generally there will be no raw rubber problems. However, it is often due to reasons that have not attracted the attention of the operator, or to speed up the melting of the glue in order to speed up the production, so that the screw back speed is quite fast, for example, it only takes two or three seconds, the screw will return to the maximum melt amount At more than one-fifth of the position, the PVC material is heated and stirred for a short period of time, which causes the problem of raw rubber temperature and uneven mixing. The strength and toughness of the injection molded parts will become quite poor.

Therefore, when injecting PVC pellets, be careful not to adjust the melt speed to more than 100 rpm. If it must be adjusted fairly quickly, remember to increase the material temperature by 5 to 10 ° C, or increase the back pressure of the melt appropriately to match, and also pay attention to frequently check for raw rubber problems, otherwise it is very likely Cause significant losses.

Regarding this issue, since most people do not care too much, it is specially proposed to remind the production must pay attention, and remember to do a good job of inspection.

On the contrary, it should also be noted that if the melt speed is too slow, even 180-degree injection of PVC 90-degree pellets will cause burning problems. Especially for transparent PVC pellets, there will be many black spots and air marks on the injection molded parts. produce.

Wuxi Jiahong Plastics Technology Co., Ltd. has nearly 30 years of experience in research and development of PVC compund, granulation production, R & D and production of modified engineering plastics; a professional technical service team can provide customers with one-stop modified plastic system solutions. If you want to know more about the product, please log in to our official website: www.jingweiclub.cn, consult the online customer service or call the hotline. Telephone: 0510-68755207 Mobile: 15190220696, we will serve you wholeheartedly.

(Disclaimer: All the tutorials and resources included in this site are from the Internet, and their copyrights belong to the original authors and their websites. Although this site strives to preserve the original copyright information, it may not be determined due to many reasons. The true source, please forgive the original author! If you have any objections to the attribution of the tutorials and resources on this site, please notify the editor immediately. If the situation is true, we will delete it as soon as possible.)